Nippon Mektron, Ltd. receives orders to supply FPC for Volkswagen ID.2

PRESS RELEASE

Nippon Mektron, Ltd. receives orders to supply FPC for Volkswagen ID.2

Scheduled to start production in 2026

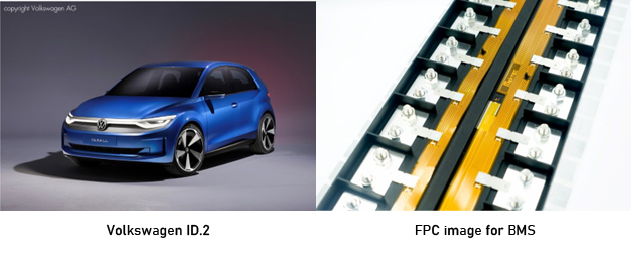

Nippon Mektron, Ltd. (Headquarters: Shibadaimon, Minato-ku, Tokyo, Representative Director, President: Taro Ito; hereinafter referred to as “Nippon Mektron”) received orders from Volkswagen AG (Headquarters: Wolfsburg, Germany) in February 2024 to supply flexible printed circuits (FPC) for the battery management system (BMS) installed in Volkswagen ID.2. Full-scale production of these orders is scheduled to start in 2026. This is Nippon Mektron’s first direct business with VW, and total sales from these orders are expected to exceed 400 million euros.

Nippon Mektron is a pioneer in the development of FPC for BMS and boasts the world’s top market share. It is capable of full-scale manufacturing in Europe, from material development to the mounting of various components on FPC. These orders will be manufactured at its plant in Hungary*1, which is IATF16949*2 and VDA6.3*3 certified, in compliance with the quality control standards for automobiles that NOK Group has developed over many years.

About FPC for BMS:

FPC for BMS used in automotive batteries is connected to each cell of the battery and prevents over-discharge and over-charge by measuring and sensing the voltage in the cell at any time. The use of FPC also makes it possible to automate the battery installation process by integrating electronic components, connectors, and busbars into the FPC.

About Nippon Mektron’s FPC for Automotive Applications:

Nippon Mektron started manufacturing FPC for automotive applications in the 1990s. In addition to BMS, its FPC is used for lighting, infotainment, sensors, heaters, and other applications. It develops its own materials and provides FPC that meet a variety of needs, such as high voltage resistance, heat resistance and heat dissipation, and high current capability. It also manufactures globally in Japan, China, Europe, and other countries, supplying car and battery manufacturers around the world.

*1 Mektec Manufacturing Corporation Europe HU Kft. Address: Határ út 4, 2119 Pécel, Hungary

*2 IATF16949

IATF16949 is an international standard for quality management systems specific to the automotive industry. It certifies organizations that have established a quality management system to prevent defects, reduce variation and waste in the supply chain, and achieve continuous improvement.

*3 VDA6.3

VDA6.3 is a requirement by the German Association of the Automotive Industry to audit not only the process control of manufacturing but also the project management system. Factories that possess a high level of quality for the mass production of automotive parts are certified.

Nippon Mektron, Ltd.

Business Lines: Manufacturing, importing, and selling electronic products.

Head Office: 1-12-15 Shibadaimon, Minato-ku, Tokyo 105-8585, Japan